The Importance and Choice of Installation Direction of Flange Ball Valves

Date: 2025-06-15 Categories: Valve Knowledge Views: 5288

Excerpt:

Although flange ball valves can theoretically be installed in both directions, the actual installation direction needs to be carefully determined according to the characteristics of the fluid (such as pressure fluctuations, impurities) and specific process requirements to ensure valve performance, sealing effect and safe and stable operation of the pipeline system.

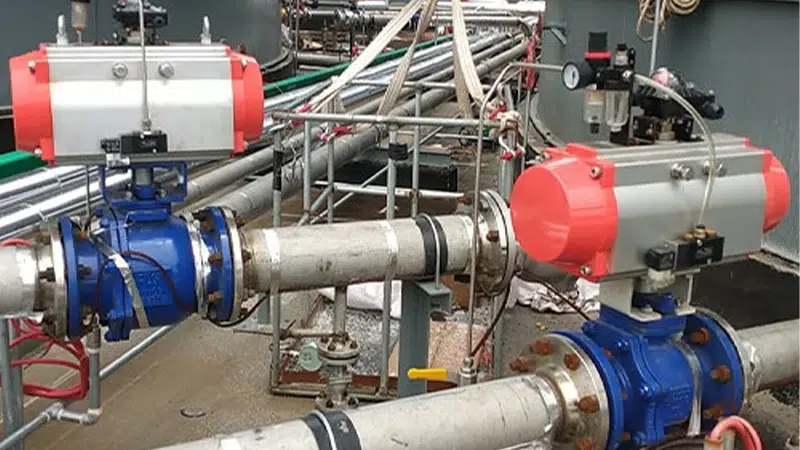

In industrial piping systems, flanged ball valves are a critical type of valve, and their proper installation is essential to the performance of the valve and the smooth operation of the piping system.

From the analysis of fluid mechanics, although most flange ball valves have the characteristics of bi-directional sealing, theoretically supporting bi-directional installation, but in practice, the choice of installation direction still requires careful consideration.

When there are pressure fluctuations or shocks in the fluid in the pipeline, it is reasonable to place the inlet end of the ball valve on the side where the pressure is smoother. This will help reduce the impact of the fluid on the ball and sealing surface, thereby improving the durability of the valve. For example, in large water supply and drainage systems, the inlet side of the pressure is usually more stable, the ball valve will be installed so that the water flow from this end of the inflow, you can effectively reduce the damage to the valve due to rapid changes in pressure.

When dealing with fluid pipelines containing impurities or particles, it should be ensured that the fluid flows from below the sealing surface of the valve seat to minimize the accumulation of impurities and particles on the sealing surface and maintain the sealing effect of the valve. In the case of mine tailings transportation pipelines, for example, the correct installation direction can prevent the influence of impurities on the closing performance of the valve and avoid the occurrence of leakage problems.

In addition, in the specific process requirements of the piping system, the installation direction must strictly comply with the process specification. For example, in some chemical production processes, in order to accurately control the chemical reaction, the direction of fluid flow must follow the design requirements, at this time the installation direction of the flange ball valve must match the specified flow direction.

Therefore, although some flange ball valves can theoretically be installed in both directions, but in the actual installation, it is necessary to comprehensively consider the characteristics of the fluid, pressure conditions and process requirements, to ensure that the installation direction is appropriate, in order to protect the valve and the entire piping system for safe and stable operation.