The S7B11F Hydraulically Operated Normally Closed Steam Trap (Leak-Free, High-Efficiency, Energy-Saving Steam Trap) meets all performance standards specified in national standards GB12251-89 and ZBJ16007-90. Combining the advantages of both inverted bucket and free float designs, this valve features a simple structure with only the float as the moving component. It operates stably and reliably while delivering high efficiency and energy savings. It is widely applied in steam networks, heating equipment, air compressors, air dryers, and other related fields.

Working Principle

When no condensate is present in the valve, the float ball seals the valve opening tightly under its own weight and the system's gas pressure. As the condensate level rises to a certain height, the float ball ascends steadily due to the buoyancy force of the liquid, opening the valve to discharge the condensate. When the water level drops to a predetermined position, the valve closes rapidly through the combined action of gas pressure and the float ball's weight, while retaining a certain amount of water at the valve base to form a water seal.

Performance Characteristics

- The valve seat and valve opening are made of special materials with high hardness and wear resistance, and buffer parts are attached, so the service life is long. The national standard service life of mechanical traps is ≥8,000 hours, and the service life of this valve is greater than 16,000 hours.

- Features a dual sealing system: valve port seal and water seal. Steam traps with other designs both domestically and internationally exhibit some steam leakage rate. The national standard permits a leakage rate ≤3%, while this valve achieves a leakage rate of approximately 0. This significantly reduces energy consumption and enhances thermal efficiency.

- High back pressure ratio, reaching 99%, with subcooling of 0°C, making it more suitable for thermal energy recovery and reuse. National professional standards (ZBJ16007-90) stipulate that the back pressure ratio for mechanical steam traps must be ≥80%.

- The condensate discharge correction factor, also known as the safety factor, is low and straightforward to calculate. Generally, setting the correction factor to approximately 1.5 is sufficient, eliminating the need for calculations by a professional thermal engineer.

- No need for regular maintenance, usually open the bypass valve when driving a cold car, you can flush away the impurities, to bring the user affordable and convenient.

- At atmospheric pressure, it can drain condensate continuously from the equipment system until completely emptied. This prevents condensate accumulation inside the equipment even during shutdown, providing long-term maintenance benefits while eliminating the risk of water hammer in pipelines.

- Simple installation. By combining the bypass and steam piping into a single installation, it reduces user costs and simplifies complex piping networks.

Installation Instructions

- The drain outlet should be positioned nearly perpendicular to the pipe, with the inlet and outlet arrows aligned with the direction of drainage flow.

- The installation location should be at the lowest point of the steam-water equipment.

- The operating pressure must not exceed the maximum working pressure specified for the valve.

- Before installation, all debris must be removed from the pipeline to prevent foreign objects from entering the valve.

- The bypass valve should be installed downstream of the steam trap to facilitate the removal of debris.

- Please select the correct model according to the displacement chart.

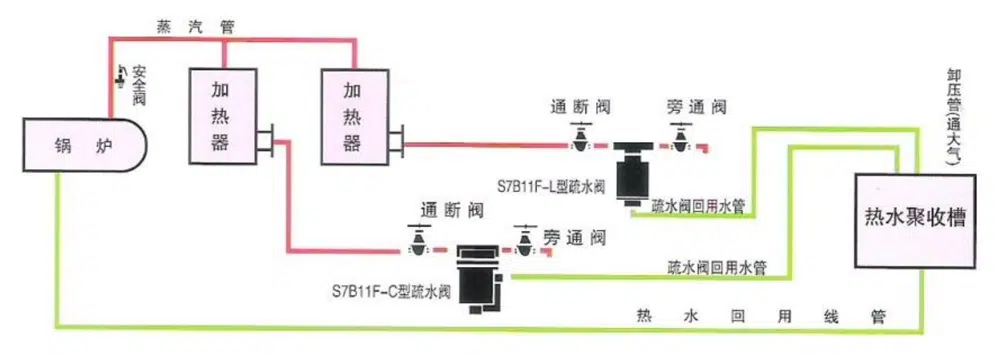

Enhancing Steam Network Production Efficiency: Installation Schematic

Energy-Saving Effect

The S7B11F-7C hydraulic normally closed steam trap achieves a maximum discharge rate of 1300 kg/h at 0.5 MPa, with a typical operating discharge rate of 60%, equivalent to discharging 780 kg/h of condensate. Energy savings: 780 kg/h × 3.1 T/h × 24 hours (per day) × 30 days ≈ 16.8 tons of steam/month. According to statistics from relevant national authorities, the production cost of industrial steam nationwide in 2025 is approximately 198 yuan/ton.

Conclusion: The S7B11F-7C hydraulically operated normally closed steam trap, operating at 0.5 MPa pressure, can save RMB 3,326 per month.

Product Parameters

Product Model | S7B11F-7C |

Valve body material | Cast Steel |

Nominal pressure | ≤0.7 MPa |

Applicable medium | Steam, Condensate, etc. |

Applicable temperature | ≤220°C |

Condensate Drainage Capacity [Maximum Drainage Capacity (kg/h) at Different Differential Pressures (MPa)]

Nominal Diameter | 0.2 MPa | 0.3 MPa | 0.5 MPa | 0.7 MPa |

DN25 | 700 kg/h | 900 kg/h | 1300 kg/h | 1600 kg/h |

DN40 | 700 kg/h | 900 kg/h | 1300 kg/h | 1600 kg/h |

DN50 | 700 kg/h | 900 kg/h | 1300 kg/h | 1600 kg/h |

Product Size Reference