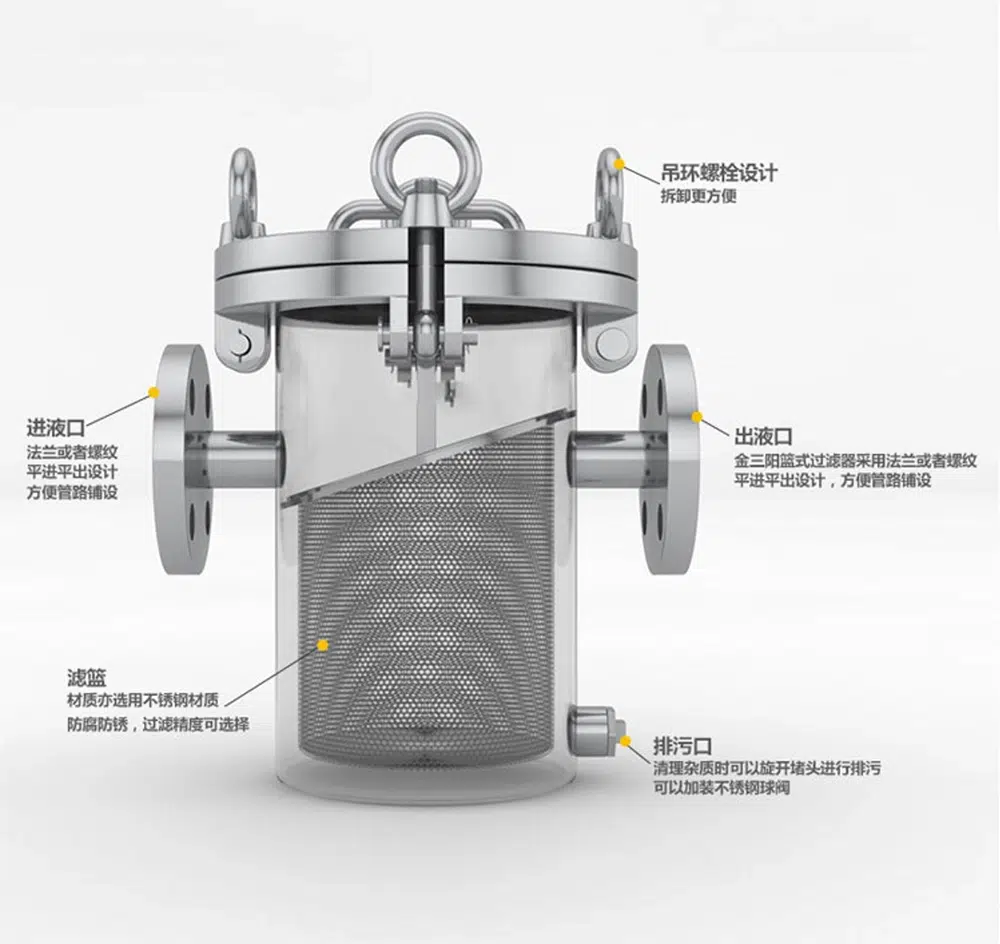

SBL basket filter is used in oil or other liquid pipeline to filter debris in the pipeline, the filter hole area is more than 2-3 times larger than the diameter pipe area, far more than the Y-type and T-type filter area. Filter precision in the filter belongs to a kind of filter with better precision, the structure of the filter mesh is not the same as other filter mesh, because of the shape like a basket, so it is called basket filter.SBL basket filter is a small equipment to remove a small amount of solid particles in the liquid, and it can protect the normal work of compressor, pump, instrument and other equipments.When the fluid enters into the filter drum with a certain specifications of the mesh filter, the impurity is blocked, and the clean filtrate is discharged by the filter outlet. When the fluid enters the filter drum with certain specifications, the impurities will be blocked and the clean filtrate will be discharged from the filter outlet. When it needs to be cleaned, it is only necessary to take out the removable filter drum and reload it after treatment, so it is extremely convenient to use and maintain. At present, it has been widely used in petroleum, chemical, pharmaceutical, food, environmental protection and other industries. If it is installed in series at the entrance of the pump or other parts of the system pipeline, it can prolong the service life of the pump and other equipment, and ensure the safety of the whole system.

Working Principle

During installation, foreign objects may enter the pipeline, and impurities are also present in the raw materials during production. When fluid flows through the filter, these impurities are captured by the filter screen. Once a certain level is reached, pressure is released through the pressure relief port, allowing the housing cover to be easily opened for cleaning the filter screen. The housing can also be cleaned via the residue discharge port.

Scope of Application

- Chemical and petrochemical production involving weakly corrosive materials such as water, ammonia, petroleum products, hydrocarbons, etc.

- Corrosive materials in chemical production, such as caustic soda, concentrated and dilute sulfuric acid, carbonic acid, acetic acid, ester acids, etc.

- Low-temperature materials in refrigeration, such as: liquid methane, liquid ammonia, liquid oxygen, and various refrigerants.

- Light industrial food and pharmaceutical production materials with hygiene requirements, such as: beer, beverages, dairy products, grain-based products, and pharmaceutical supplies.

- High-efficiency filters for various specialized processes, etc.

General Principles for Filter Selection

- Inlet and outlet diameters: In principle, the inlet and outlet diameters of the filter should not be smaller than the inlet diameter of the corresponding pump. They are generally consistent with the inlet pipe diameter.

- Nominal Pressure: Determine the filter's pressure rating based on the maximum pressure that may occur in the filtration pipeline.

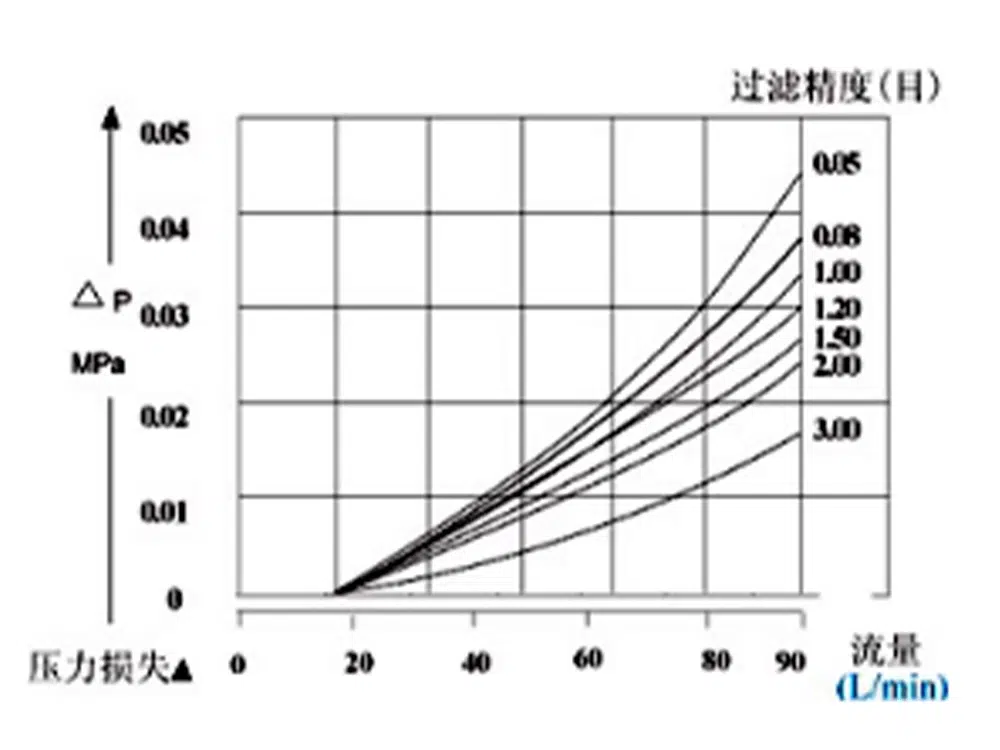

- Selection of Mesh Count: Primarily determined by the particle size of contaminants to be intercepted, based on the process requirements of the medium flow. Refer to the table “Filter Mesh Specifications” below for the particle sizes interceptable by various mesh specifications.

Use and Maintenance

- The core component of the filter is the filter element, which consists of a filter frame and stainless steel wire mesh. The stainless steel wire mesh is a wear-prone part and requires special protection.

- After the filter has been in operation for a period of time, impurities accumulate within the filter cartridge. This causes an increase in pressure and a decrease in flow rate, necessitating the timely removal of impurities from the filter cartridge.

- When cleaning impurities, take special care to ensure the stainless steel wire mesh on the filter element remains undistorted and undamaged. Otherwise, a damaged filter element will result in filtered media failing to meet purity specifications, potentially causing damage to compressors, pumps, instruments, and other equipment.

- If stainless steel wire mesh is found to be deformed or damaged, it must be replaced immediately.

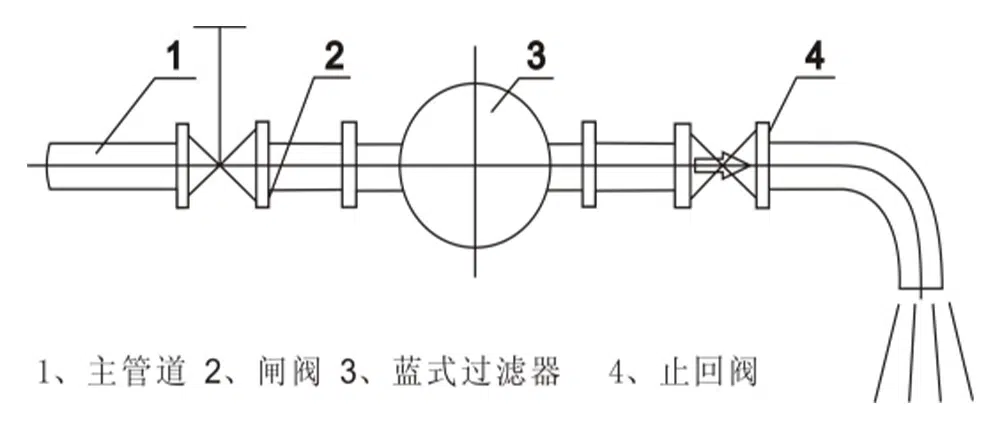

Pipe Installation Diagram

Product Parameters

Product Model | SBL-16C |

Valve body material | WCB Carbon Steel |

Nominal pressure | ≤1.6Mpa |

Applicable medium | Water, Gas, Liquids, Oils, etc. |

Applicable temperature | ≤150°C |

Product Size Reference

Nominal Diameter | L | D | H1 | H | sewer outfall | Effective filtration area (m³) |

DN50 | 285 | 108 | 170 | 300 | 1/2 | 0.0315 |

DN65 | 320 | 140 | 240 | 360 | 1/2 | 0.0461 |

DN80 | 340 | 159 | 250 | 400 | 1/2 | 0.0590 |

DN100 | 430 | 219 | 300 | 470 | 1/2 | 0.1077 |

DN125 | 440 | 273 | 360 | 550 | 1/2 | 0.1759 |

DN150 | 500 | 273 | 420 | 630 | 1/2 | 0.2910 |

DN200 | 540 | 325 | 530 | 780 | 3/4 | 0.4076 |

DN250 | 600 | 426 | 640 | 930 | 3/4 | 0.5016 |

DN300 | 700 | 450 | 840 | 1200 | 3/4 | 0.6800 |

DN350 | 750 | 500 | 920 | 1370 | 3/4 | 0.7200 |

DN400 | 800 | 550 | 950 | 1500 | 1 | 0.8120 |

DN450 | 900 | 600 | 1000 | 1700 | 1 | 0.8900 |

DN500 | 1000 | 700 | 1050 | 1910 | 1 | 0.9502 |