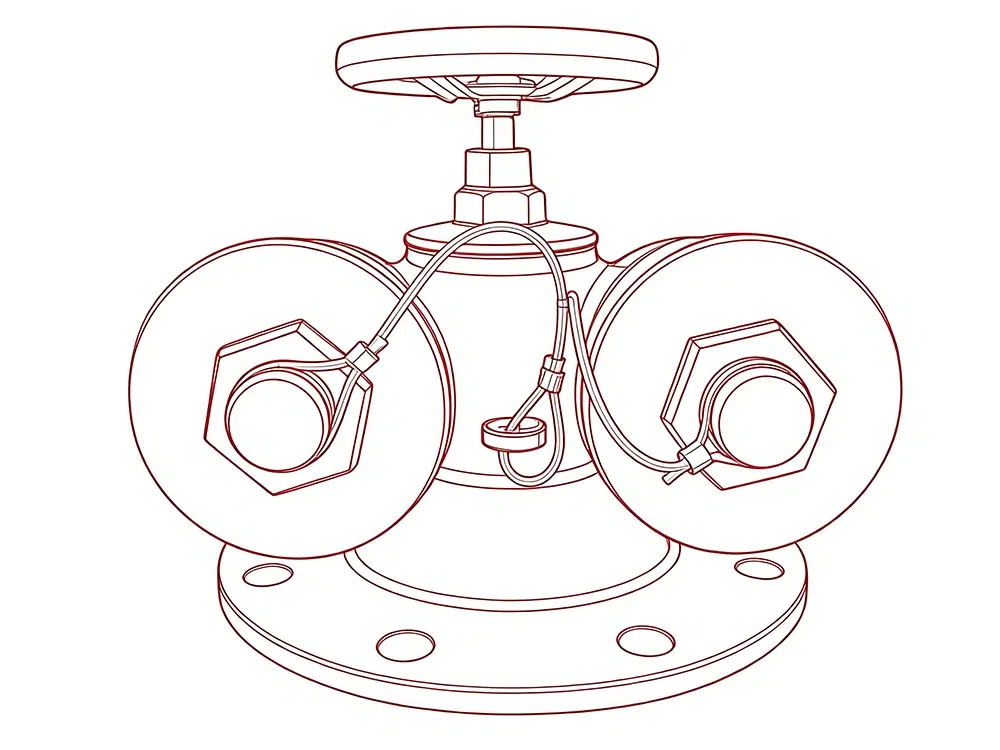

The SQD multi-purpose fire pump coupling is a connecting device used by fire trucks and portable pumps to supply firefighting water and other liquid extinguishing agents to building fire water supply systems. It addresses challenges faced by fire trucks in high-rise buildings during firefighting operations, such as insufficient water supply or intermittent water flow due to low pressure in internal fire water pipelines. Typically installed in densely populated areas and locations requiring firefighting capabilities, such as factories, warehouses, docks, freight yards, and public spaces within high-rise buildings. The product features a rational structure, reliable performance, and user-friendly operation.

Working Principle

When supplying water to the water supply system, the pressurized water is transported to the site through the interface, body, elbow, check valve, safety valve and gate valve of the fire pump connector in order. Check valves play a role in preventing the backflow of liquid; safety valves so that the pressure in the pipeline does not exceed the prescribed value, and play a role in automatically protecting the pipeline; gate valves play a role in connecting or cutting off the water flow.

Installation and Use

- Before installation, remove dirt and debris from the fire pump hydrant and connecting pipes to prevent poor sealing.

- During installation, handle with care to avoid damaging valve components.

- When using, first close the drain valve, open the gate valve to its maximum height, remove the cap, connect the hose, and supply water from the fire truck to the fire pump coupling. Extinguishing operations can be completed using the indoor hydrant, hose, and nozzle. After extinguishing, open the drain valve to empty residual water and replace the cap.

Maintenance and Care

- Regularly inspect all components of the multi-purpose fire pump hydrant to ensure they are in good working order and that all valves operate smoothly. After each use, lubricate the gate valve stem with oil.

- Inspect all gaskets at the joint surfaces to ensure they are intact. Replace any damaged gaskets immediately.

- Promptly remove any obstructions near the multi-purpose fire pump hydrant.

- After winter use, open the drain valve to completely empty any remaining water, then securely close the lid. This prevents the unit from freezing and cracking.

- Maintenance and servicing must be performed by qualified personnel.

Product Parameters

Product Model | SQD100/150-1.6 |

Valve body material | Ductile Iron |

Nominal pressure | ≤1.6Mpa |

Applicable medium | Water-Foam Mixture |

Applicable temperature | ≤80°C |

Product Size Reference

model number | Nominal pressure Mpa | Nominal diameter mm | water inlet |

SQD100-1.6 | 1.6 | 100 | 2-KWS65 |

SQD150-1.6 | 1.6 | 150 | 2-KWS80 |