The plunger surface of U41S-16C cast steel plunger valve is processed by high-precision cylindrical grinder, and the sealing ring is made of new non-toxic sealing material with strong elasticity and high abrasion resistance, so the sealing is reliable and durable, which improves the service life of the plunger valve. Flange plunger valve standard can be processed according to American Standard, Japanese Standard, National Standard and so on. Installed in the steam pipeline, no leakage in the stem area, is one of the commonly used valves in the boiler steam pipeline. No fluid loss improves the use of energy efficiency, increases the safety of production equipment, reduces maintenance costs and frequent maintenance, reduces operating costs, but also provides a clean and safe working environment.

Working Principle

When the handwheel is rotated, the cast steel plunger valve operates by driving the plunger to reciprocate vertically within the bore frame, thereby achieving valve opening and closing. A interference fit is employed between the plunger and sealing ring. By adjusting the flange bolts in the gland, the lateral force generated by compressing the sealing ring ensures sealing against the bore surface of the valve body and the outer circumference of the plunger, thus guaranteeing the valve's sealing integrity.

Product Features

- When switching the plunger valve, the plunger moves slowly within the seal ring, causing minimal wear on the contact surfaces.

- The sealing ring utilizes a novel, non-toxic sealing material with high elasticity and wear resistance, ensuring reliable sealing and long-lasting durability.

- The valve employs an interference fit between the piston and sealing ring, ensuring the valve's sealing integrity and eliminating both internal and external leakage.

- When closed, the plunger inserts into the lower seal ring, blocking the flow channel. When opened, although the plunger disengages from the lower seal ring, it remains housed within the upper seal ring, maintaining isolation from the external environment to prevent leakage.

Product Parameters

Product Model | U41S-16C |

Valve body material | Cast Steel |

Nominal pressure | ≤1.6Mpa |

Applicable medium | Water, Steam, Oil, etc. |

Applicable temperature | ≤250°C |

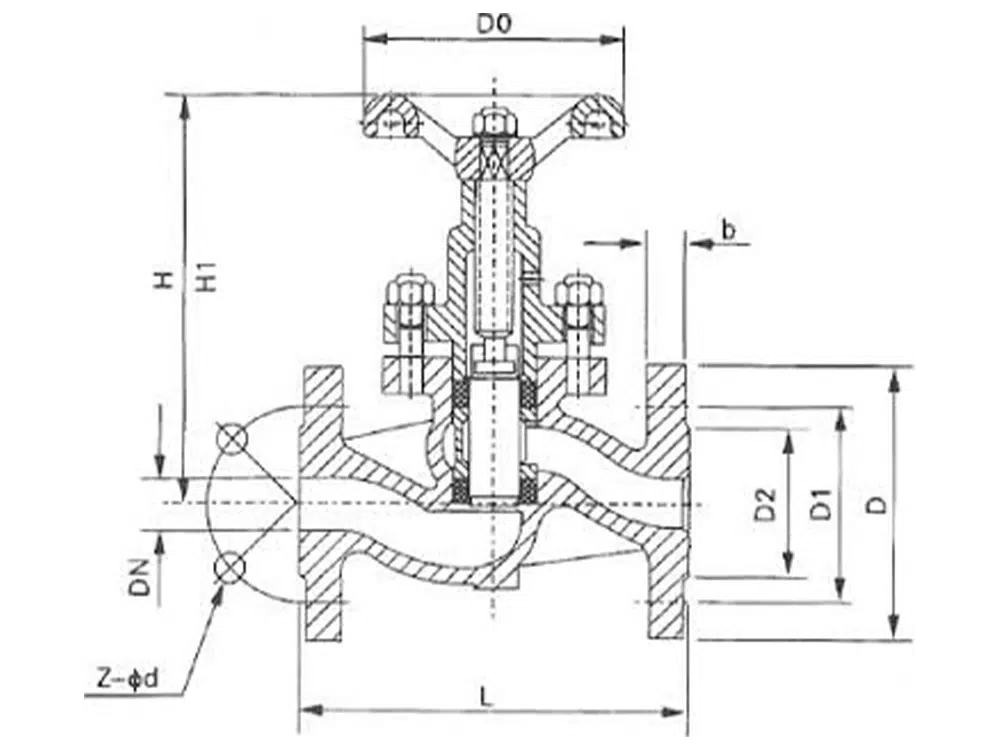

Product Size Reference

DN | L | D | D1 | D2 | b | z-Φd | H | H1 | D0 |

15 | 130 | 95 | 65 | 45 | 14 | 4-14 | 116 | 144 | 85 |

20 | 150 | 105 | 75 | 55 | 16 | 4-14 | 142 | 176 | 85 |

25 | 160 | 115 | 85 | 65 | 16 | 4-14 | 163 | 205 | 100 |

32 | 180 | 135 | 100 | 78 | 18 | 4-18 | 182 | 227 | 120 |

40 | 200 | 145 | 110 | 85 | 18 | 4-18 | 210 | 260 | 140 |

50 | 230 | 160 | 125 | 100 | 20 | 4-18 | 230 | 286 | 160 |

65 | 290 | 180 | 145 | 120 | 20 | 4-18 | 250 | 310 | 180 |

80 | 310 | 195 | 160 | 135 | 22 | 8-18 | 269 | 340 | 200 |

100 | 350 | 215 | 180 | 155 | 24 | 8-18 | 278 | 356 | 240 |

125 | 400 | 245 | 210 | 185 | 26 | 8-18 | 332 | 440 | 375 |

150 | 480 | 280 | 240 | 210 | 28 | 8-23 | 434 | 562 | 375 |

200 | 600 | 335 | 295 | 265 | 30 | 12-23 | 498 | 660 | 460 |

250 | 700 | 405 | 355 | 320 | 38 | 12-23 | 540 | 660 | 460 |

300 | 750 | 460 | 410 | 360 | 38 | 12-23 | 650 | 680 | 460 |