J41B ammonia globe valve has stable sealing performance, safe and reliable use, strong corrosion resistance, no media leakage and lightweight operation, successfully solved the chemical pipeline with ordinary valves poor corrosion resistance, easy to perforate the shell as well as poor sealing performance, easy to leak the problem. Especially suitable for chemical industry ammonia, gas pipeline transmission, and to meet the requirements of long-term reliable use of its sealing, maintainability, safety and so on. Widely used in freezing, refrigeration, chemical, petroleum, food, smelting, liquefied gas and other industries.

Product Features

- Aiming at the shortcomings of ordinary valves with poor corrosion resistance and easy perforation of the shell, according to the specific characteristics of the medium, the ammonia valve is made of corrosion-resistant steel (low-temperature carbon steel with added corrosion-resistant alloying elements), which can be resistant to ammonia and liquid ammonia corrosion, and the low temperature can be as low as -40 ℃, to ensure that the use of the working conditions to the maximum extent possible requirements.

- Ammonia globe valve sealing pair structure type using ball, plane type, sealing automatic compensation, to achieve the effect of double insurance, stable sealing performance, no adhesive wear, effectively solve the chemical pipeline with ordinary valves with poor sealing performance, easy to leak the problem.

- The center flange of the product adopts a concave-convex sealing structure, which ensures absolutely reliable sealing of the center flange even under fluctuating pipeline pressure.

- Multi-stage PTFE sealing material is used in the upper sealing device to form a combination of sealing to ensure that the valve has no leakage of medium in the packing box during the service life, eliminating the possibility of weak sealing of the packing box of ordinary valves and easy leakage of medium, even causing accidents.

Product Parameters

Product Model | J41B-25C |

Valve Body Material | Cast Steel |

Nominal Pressure | ≤2.5Mpa |

Applicable Media | Ammonia Gas, Ammonia Solution, etc. |

Operating Temperature | ≤150°C |

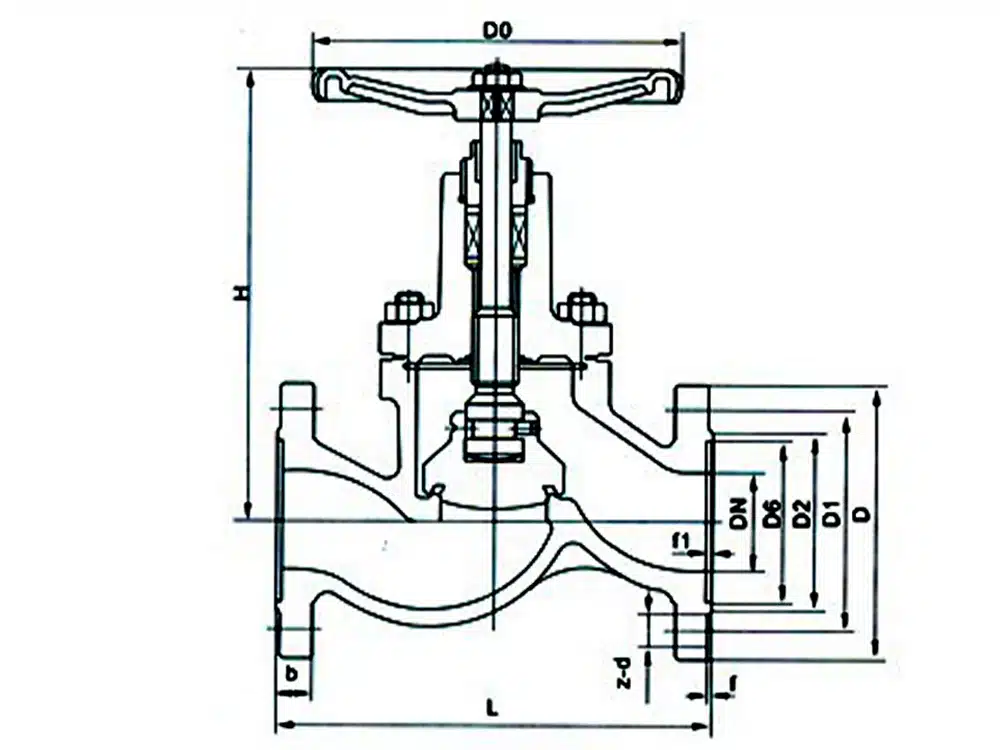

Product Size Reference

DN | L | D | D1 | D2 | D6 | b | f | f1 | z-d |

15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-14 |

20 | 150 | 105 | 75 | 55 | 51 | 18 | 2 | 4 | 4-14 |

25 | 160 | 115 | 85 | 65 | 58 | 18 | 2 | 4 | 4-14 |

32 | 180 | 135 | 100 | 78 | 66 | 20 | 2 | 4 | 4-18 |

40 | 200 | 145 | 110 | 85 | 76 | 20 | 3 | 4 | 4-18 |

50 | 230 | 160 | 125 | 100 | 88 | 22 | 3 | 4 | 4-18 |

65 | 290 | 180 | 145 | 120 | 110 | 24 | 3 | 4 | 8-18 |

80 | 310 | 195 | 160 | 135 | 121 | 26 | 3 | 4 | 8-18 |

100 | 350 | 230 | 190 | 160 | 150 | 30 | 3 | 4.5 | 8-23 |

125 | 400 | 270 | 220 | 188 | 176 | 32 | 3 | 4.5 | 8-25 |

150 | 480 | 300 | 250 | 218 | 204 | 32 | 3 | 4.5 | 8-25 |

200 | 600 | 360 | 310 | 278 | 260 | 34 | 3 | 4.5 | 12-25 |

250 | 650 | 425 | 370 | 335 | 310 | 36 | 3 | 4.5 | 12-30 |

300 | 750 | 485 | 430 | 390 | 364 | 40 | 3 | 4.5 | 16-30 |