T10F-16T brass manual control valve is suitable for frequent operation, open and close quickly, lightweight; fluid resistance is small, simple structure, relatively small size, easy maintenance. Adjustment valve sealing performance is good, manually adjustable need flow range, not subject to the installation direction of installation restrictions, the media flow direction can not be limited. Clockwise rotation of the handwheel can be closed manually adjustable valve, the valve stem drives the valve flap down, until the two conical sealing surface contact to reach the forbidden pipeline closure.

Product Features

- Improvement of heating conditions: Where the use of manual control valve line and heat points, can be designed according to the conditions of flow regulation, to achieve a good temperature conditions, this control valve than the gate valve, globe valve regulating performance is good, it has an approximate straight-line regulation performance, therefore, the heating building cold and hot uneven phenomenon has been a powerful improvement.

- Energy saving: the heat pipe network due to temperature and pressure imbalance, resulting in some tributaries are too large, so that some building temperature is too high, the user has to open the window, a large amount of heat energy wasted, due to the installation of the branch of the manual regulator valve, to overcome the temperature and pressure imbalance, to avoid opening the window, and to achieve the purpose of energy saving.

- Improvement of pipe network hydraulic conditions: manual adjustment valve can be controlled in accordance with the rated flow rate, the pipe network overrun to reduce the flow rate, so that the original degree of deterioration of the water working conditions have been improved to a certain extent.

Product Parameters

Product Model | T10F-16T |

Valve Body Material | Brass |

Nominal Pressure | ≤1.6Mpa |

Applicable Media | Water, etc. |

Operating Temperature | ≤80°C |

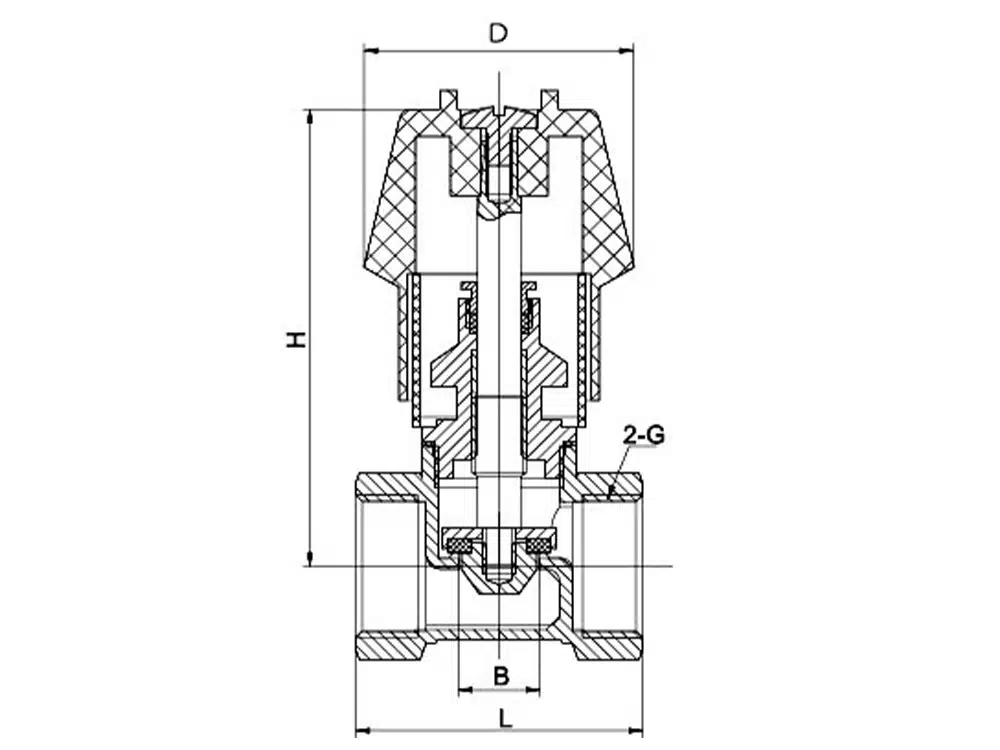

Product Size Reference

Nominal Diameter | SIZE | L | B | H | D |

DN15 | 1/2 | 46 | 12 | / | / |

DN20 | 3/4 | 53 | 15 | 84 | 50 |

DN25 | 1 | 61 | 19 | 85 | 50 |

DN32 | 1-1/4 | 67 | 28 | 92 | 50 |

DN40 | 1-1/2 | 75 | 32 | / | / |

DN50 | 2 | 93 | 42 | / | / |