ZPG automatic backwashing filter overcomes many shortcomings of traditional filtration products such as small dirt-holding capacity, easy to be clogged by dirt, filtration part needs to be disassembled and cleaned, and it cannot monitor the filtration status, etc. It has the function of filtering raw water and automatically cleaning and discharging the cartridge, and the system does not interrupt the water supply during the cleaning and discharging process, and it can monitor the filter's working status, and the degree of automation is relatively high. The backwashing filter can be installed in vertical, horizontal and inverted positions in any direction, and can be used for water filtration in various industries such as industry, agriculture, municipal electric power, electronics, medicine, food, printing and dyeing, construction, iron and steel, metallurgy, paper making and so on.

Working Principle

- Working Filter: During normal operation, the water flow direction valve remains open. Water requiring treatment passes through the filter screen, where the principle of inertia causes fine particulate matter and suspended solids to settle near the drain outlet.

- Backwashing and Drainage: During normal operation, the water flow direction valve remains open. When the filter screen accumulates a sufficient quantity of fine particulate matter and suspended solids, open the valve on the drain port. The water flow will then flush away the accumulated impurities from the filter collection section until the discharged water becomes clear. Close the drain port valve to resume normal operation.

- Backwash Drainage: During backwashing, the flow direction valve remains closed while the drain valve opens. Water is forced through the mesh openings at the inlet section of the filter cylinder into the space between the filter cylinder and the housing. This reverse flow flushes contaminants adhering to the mesh from the outside of the cylinder, achieving thorough cleaning of the filter screen. With the directional valve closed, water velocity increases after passing through the backwash valve, enhancing the backwash effectiveness.

Installation Instructions

ZPG-type (angular) automatic backwashing sewage filter should be installed on the right-angle bend, ZPG-type (straight-through) automatic backwashing sewage filter should be installed horizontally or vertically, when the straight-through is installed vertically, the direction of the water flow should be top-down, and the arrow direction of the housing must be noted with the direction of the water flow during installation.

Product Parameters

Product Model | ZPG-16C |

Valve body material | WCB Carbon Steel |

Nominal pressure | ≤1.6Mpa |

Applicable medium | Non-Corrosive Water, Neutral Liquids, etc. |

Applicable temperature | ≤100°C |

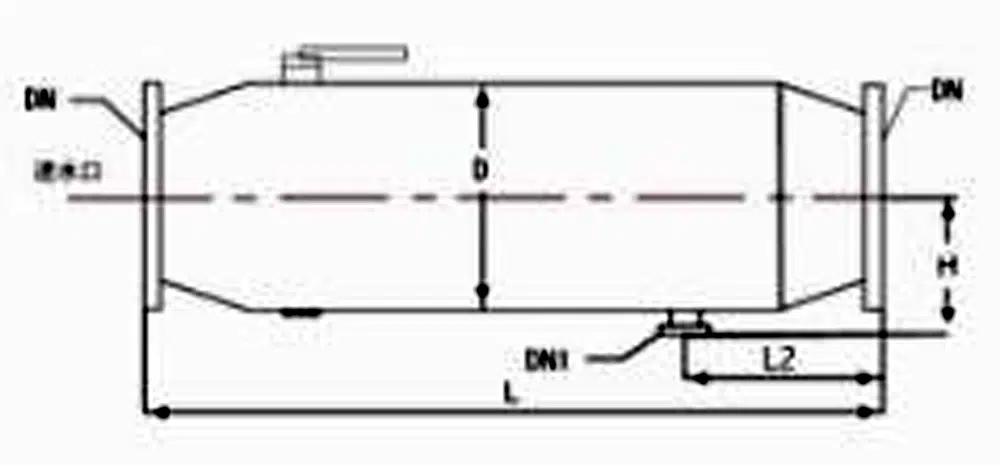

Product Size Reference

Nominal Diameter | D | DN (Outfall) | L | L2 | H |

DN40 | 76 | 15 | 350 | 70 | 88 |

DN50 | 89 | 15 | 350 | 80 | 95 |

DN65 | 108 | 20 | 350 | 95 | 108 |

DN80 | 133 | 25 | 400 | 105 | 125 |

DN100 | 159 | 32 | 500 | 110 | 145 |

DN125 | 219 | 40 | 600 | 150 | 155 |

DN150 | 273 | 50 | 700 | 180 | 210 |

DN200 | 325 | 65 | 800 | 205 | 250 |

DN250 | 377 | 80 | 970 | 230 | 275 |

DN300 | 426 | 100 | 1060 | 245 | 310 |

DN350 | 478 | 125 | 1200 | 275 | 360 |

DN400 | 560 | 150 | 1350 | 400 | 410 |

DN450 | 630 | 150 | 970 | 430 | 445 |

DN500 | 720 | 150 | 1060 | 450 | 485 |

DN600 | 820 | 150 | 1200 | 460 | 545 |