H41W lift check valve is suitable for medium and small diameter pipeline under various pressures, temperatures and media to control the opening and closing device to connect or cut off the pipeline medium; rely on the self-weight of the valve flap and the fluid pressure difference to automatically stop the fluid backflow.H41W lift check valves are widely used in the fields of water treatment, chemical industry, petrochemical industry, petroleum, papermaking, mining, electric power, liquefied petroleum gas, food, pharmaceutical industry, water supply and drainage, municipal government, electronic industry, urban construction, environmental protection, fire fighting, heating and cooling, central air conditioning, filtration equipment and other fields. environmental protection, fire fighting, HVAC, central air conditioning, filtration equipment and other fields.

Structural Characteristics

- Lift check valve has the advantages of simple structure, reliable action, easy maintenance and so on.

- When the medium from the valve body arrow shows the direction of flow into the valve body, the pressure of the medium on the valve flap to produce upward thrust, when the medium thrust is greater than the gravity of the valve flap, the valve is open. When the pressure of the medium after the valve on the force of the valve plus the valve's own gravity is greater than the pressure before the valve on the force of the valve, the valve is closed to prevent the medium from flowing backward.

- The sealing surface is not easy to wear, abrasion, better sealing, longer life.

Product Parameters

Product Model | H41W-16P |

Valve Body Material | 304 Stainless Steel |

Nominal Pressure | ≤1.6Mpa |

Applicable Media | Water, Steam, Oil, etc. |

Operating Temperature | ≤150°C |

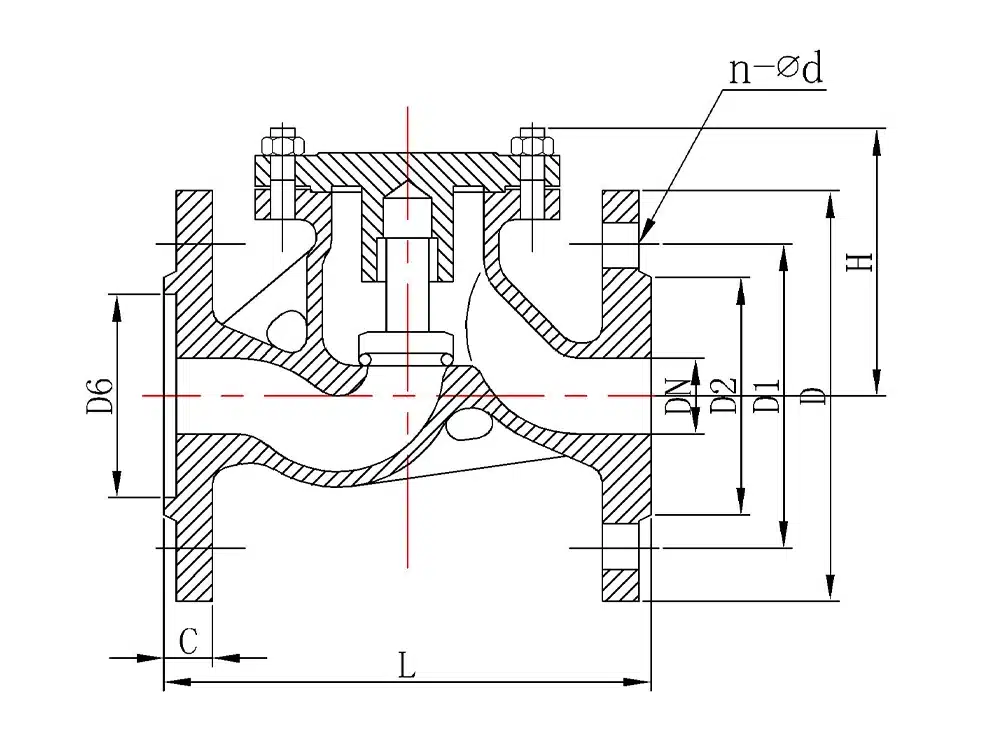

Product Size Reference

Nominal Diameter | L | D | D1 | D2 | C | n-∅d | H |

DN15 | 130 | 95 | 65 | 45 | 14 | 4-14 | 77 |

DN20 | 150 | 105 | 75 | 55 | 14 | 4-14 | 77 |

DN25 | 160 | 115 | 85 | 65 | 14 | 4-14 | 80 |

DN32 | 180 | 135 | 100 | 78 | 16 | 4-18 | 85 |

DN40 | 200 | 145 | 110 | 85 | 16 | 4-18 | 95 |

DN50 | 230 | 160 | 125 | 100 | 16 | 4-18 | 105 |

DN65 | 290 | 180 | 145 | 120 | 18 | 4-18 | 120 |

DN80 | 310 | 195 | 160 | 135 | 20 | 8-18 | 130 |

DN100 | 350 | 215 | 180 | 155 | 20 | 8-18 | 140 |

DN125 | 400 | 245 | 210 | 185 | 22 | 8-18 | 155 |

DN150 | 480 | 280 | 240 | 210 | 24 | 8-23 | 180 |

DN200 | 600 | 335 | 295 | 265 | 26 | 12-23 | 211 |

DN250 | 650 | 405 | 355 | 320 | 30 | 12-25 | 260 |

DN300 | 750 | 460 | 410 | 375 | 30 | 12-25 | 323 |

DN350 | 850 | 520 | 470 | 435 | 30 | 16-25 | / |

DN400 | 950 | 580 | 525 | 485 | 36 | 16-30 | / |