Wet alarm valve device with pressure switch, water flow indicator, sprinkler nozzle, signal butterfly valve, end of the water test device, sprinkler pump, etc. ZS series wet automatic sprinkler system, is currently the most widely used automatic sprinkler system.

Product Features

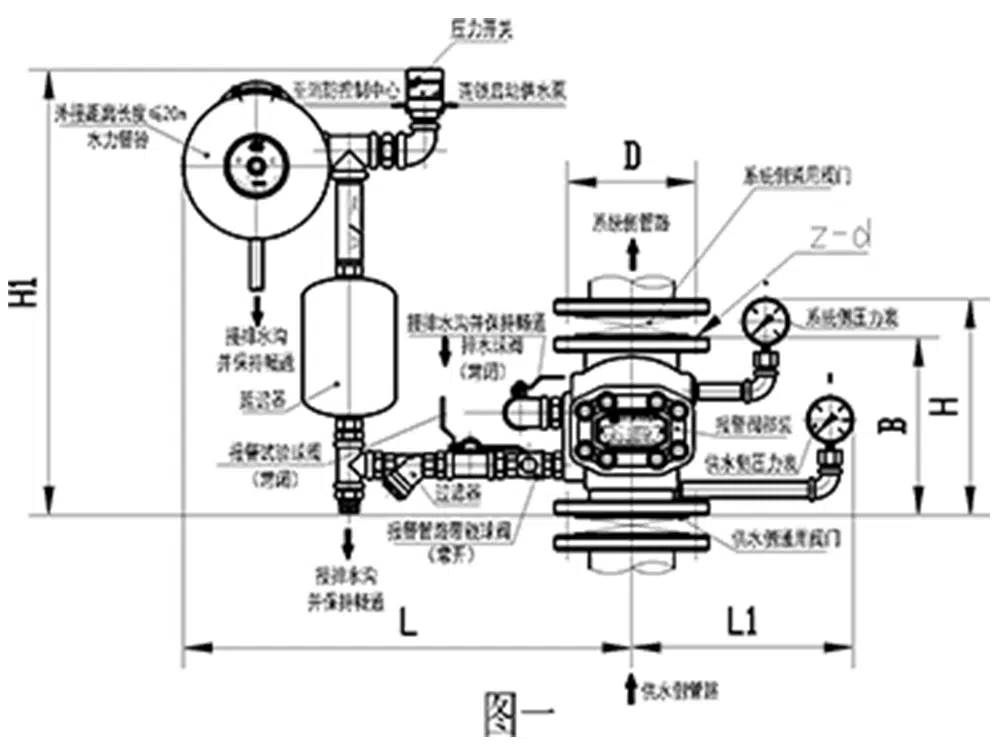

Wet alarm valve only allows water to flow unilaterally into the sprinkler system and alarm under the specified flow rate of a one-way valve. It is used for wet fire extinguishing system which is filled with water in the pipe network, the system is in standby working condition for a long time, and the pipe network is filled with pressurized water. When a fire occurs somewhere in the protected area, one or more nozzles work, the valve automatically opens to let the water keep flowing to the fire area. At the same time, the hydraulic alarm is activated and the pressure switch sends out an alarm signal.

Working Principle

Wet Alarm Valve normally the water pressure before and after the valve flap is equal (water through the guide pipe in the water pressure balance hole, to maintain the balance of water pressure before and after the valve flap). Due to the self-weight of the valve flap and the valve flap before and after the total pressure of the water is different, the valve flap is in a closed state (the total pressure above the valve flap is greater than the total pressure below the valve spool). When a fire occurs, the closed nozzle spray water, due to water pressure balance hole too late to make up for the water, the alarm valve above the water pressure drops, at this time the valve valve before the water pressure is greater than the valve valve after the water pressure, so the valve valve opens, to the standpipe and pipeline network water supply, at the same time, the water along the annular groove of the alarm valve into the delay, pressure switch and hydraulic alarm and other facilities, fire alarm signals and fire pumps to start. When a fire occurs in the protected area of the automatic sprinkler system, the fire ambient temperature rises, the glass ball on the closed nozzle explodes (or fusible alloy melting), the nozzle opens to spray water to extinguish the fire. At this time due to the wet alarm valve outlet side of the pipe network water pressure drop, the formation of differential pressure, the valve assembly open, the water source water constantly replenish the pipe network to extinguish the fire, while the water flow also through the sealing ring groove in the hole into the delayer, and quickly filled with a certain amount of water pressure impact hydraulic alarm bells to issue a continuous alarm sound, the pressure switch action to connect to the electrical contacts, connected to the control center, to the sound and light alarms, and at the same time, the start of the main water supply pump for fire extinguishing.

Function of Wet Alarm Valve Components

(1) Wet alarm valve: Allows water to flow into the sprinkler system in one direction only and triggers an alarm at the specified flow rate.

(2) Delay Device: Delays the activation time of the water-powered alarm bell to reduce false alarms caused by water pressure fluctuations.

(3) Hydraulic Alarm Bell: A hydraulically driven alarm device that emits a sound when the system activates.

(4) Pressure Switch: After the alarm valve activates, the pressure switch operates to close the electrical contacts.

(5) Alarm valve: Normally open during standby operation; may be closed only during inspection, maintenance, or repair.

(6) Test Alarm Bell Valve: Open this valve only during commissioning or maintenance to assess system performance.

(7) Drain valve: Drains residual water from the pipe network downstream of the valve to facilitate maintenance or nozzle replacement.

Product Parameters

Product Model | ZSFZ Series |

Nominal diameter (mm) | DN100~DN250 |

Rated working pressure (MPa) | 1.6 |

Strength test pressure (MPa) | 3.2 |

Action flow rate (L/min) | 15<Q<60 |

Delay time (s) | 5<t<90 |

Friction resistance (MPa) | <0.02 |

Alarm Loudness (DBCA) | >80 |

Product Size Reference

Model Specifications | DN | D | z-d | H1 | H | L1 | L | B |

DN100 | 100 | Φ180 | 8-Φ18 | 555 | 290 | 205 | 675 | 254 |

DN150 | 150 | Φ240 | 8-Φ22 | 580 | 290 | 270 | 650 | 280 |

DN200 | 200 | Φ295 | 12-Φ22 | 650 | 435 | 320 | 680 | 405 |

DN250 | 250 | Φ355 | 12-Φ26 | 660 | 470 | 330 | 700 | 440 |