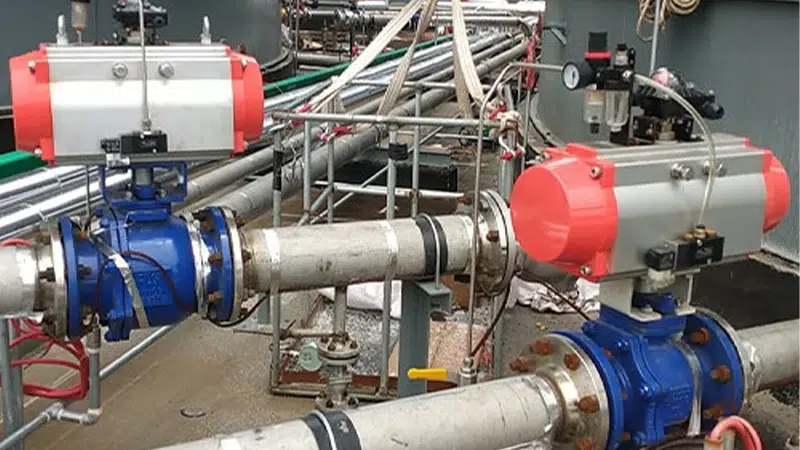

Material Selection of Seawater Valves

This paper discusses the selection of valve materials for seawater environments, emphasizing the critical impact of seawater's strong corrosive properties (containing chlorine ions, salts and microorganisms) on the safety of equipment and smooth processes. Core materials include: stainless steel (such as 316L, high corrosion resistance, strong mechanical strength, suitable for seawater treatment and marine engineering); copper alloy (corrosion resistance and antibacterial, suitable for seawater desalination and ships); plastic (lightweight and low-cost, but weak, suitable for low-pressure, small-diameter valves). When choosing, it is necessary to consider the seawater composition, process requirements and operating environment to ensure stable operation of the equipment.