Types of valves commonly used in water supply systems

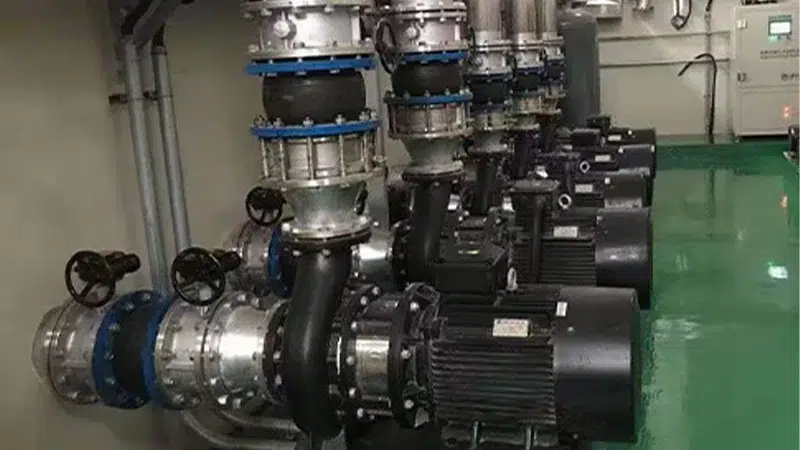

This article analyzes the water supply system five core valve types and applications: ball valves (reliable sealing, fast opening and closing, suitable for small and medium-sized pipeline cut-off); butterfly valves (lightweight and easy to operate, the main control of large flow regulation); gate valves (durable full diameter, used for the main pipeline opening and closing); check valves (to prevent the medium from backing up, to protect the safety of water pumps); regulating valves (accurate control of the flow control pressure, adapt to the precision of the water supply scenarios). Scientific selection can improve system efficiency and water supply safety.