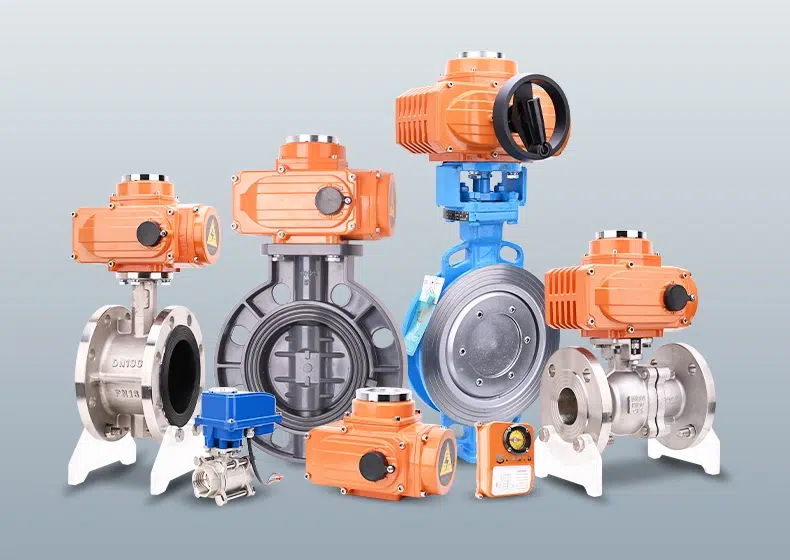

Product Showcase

About

BolaiKong Technology (Wuxi) Co., Ltd.

BolaiKong Technology (Wuxi) Co., Ltd. is situated on the beautiful and bountiful shores of Lake Tai, in Wuxi – a central city along the Shanghai-Nanjing corridor, and an economic and tourism hub in the lower reaches of the Yangtze River.

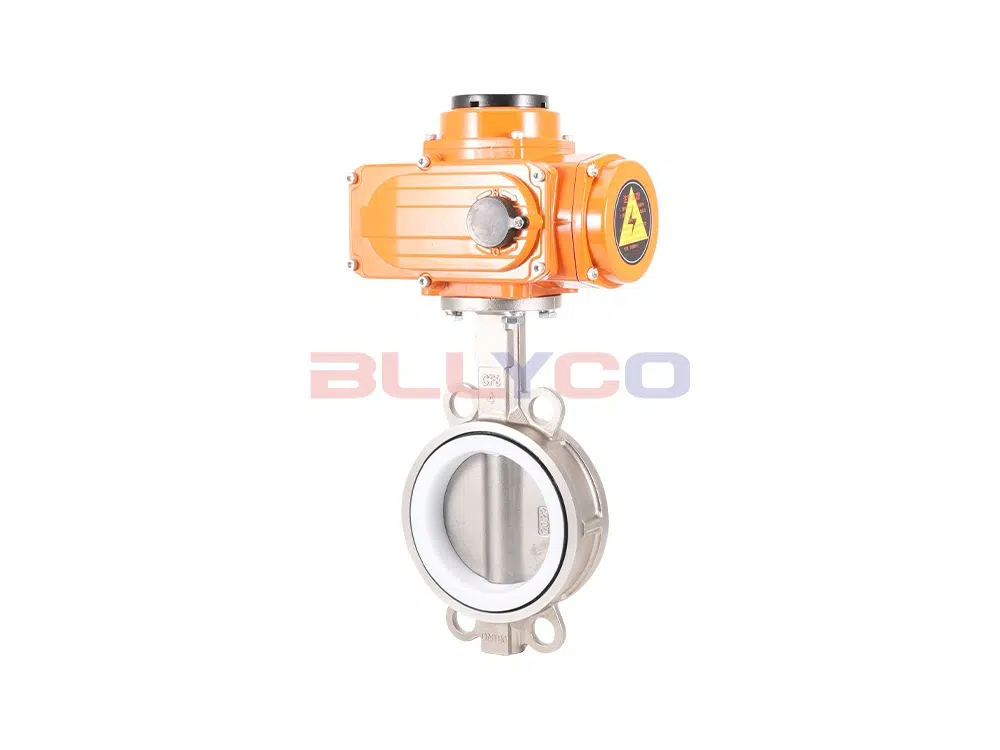

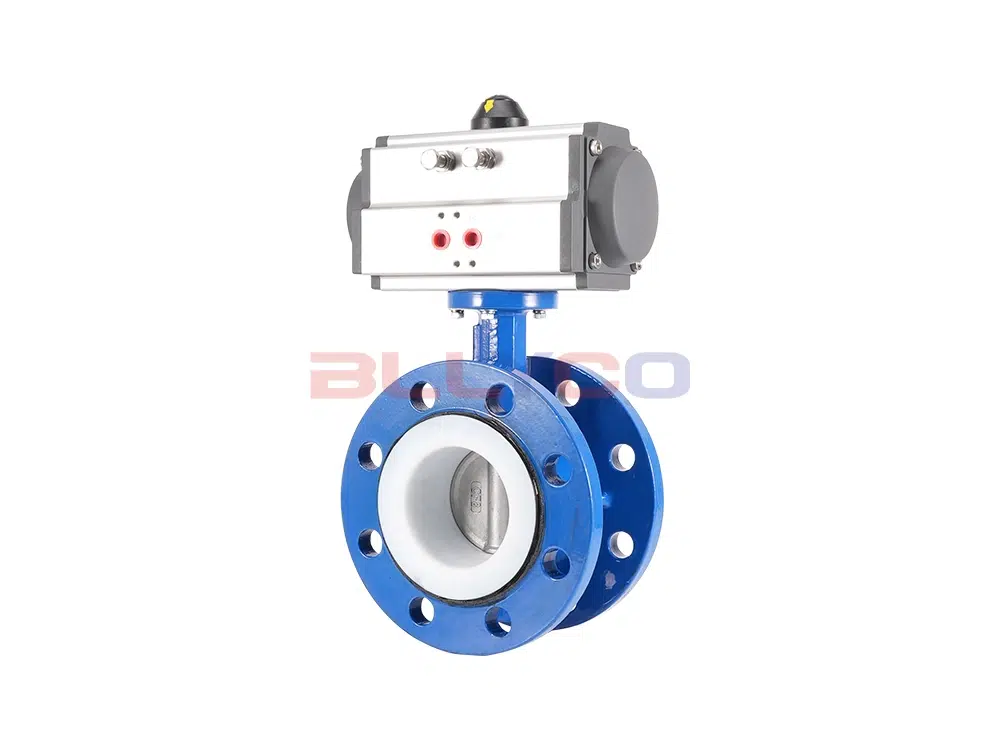

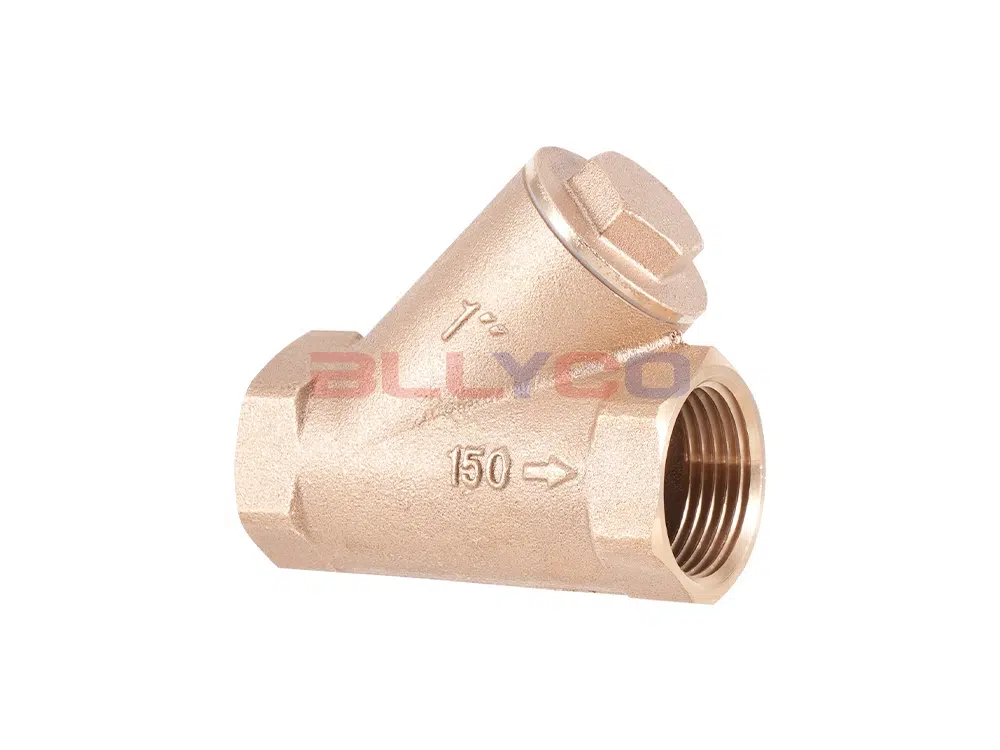

The company's leading production: ball valves, butterfly valves, gate valves, globe valves, check valves, filters, water control valves, pressure reducing valves, balancing valves, regulating valves, pneumatic valves, electric valves and other high, medium and low pressure valves.

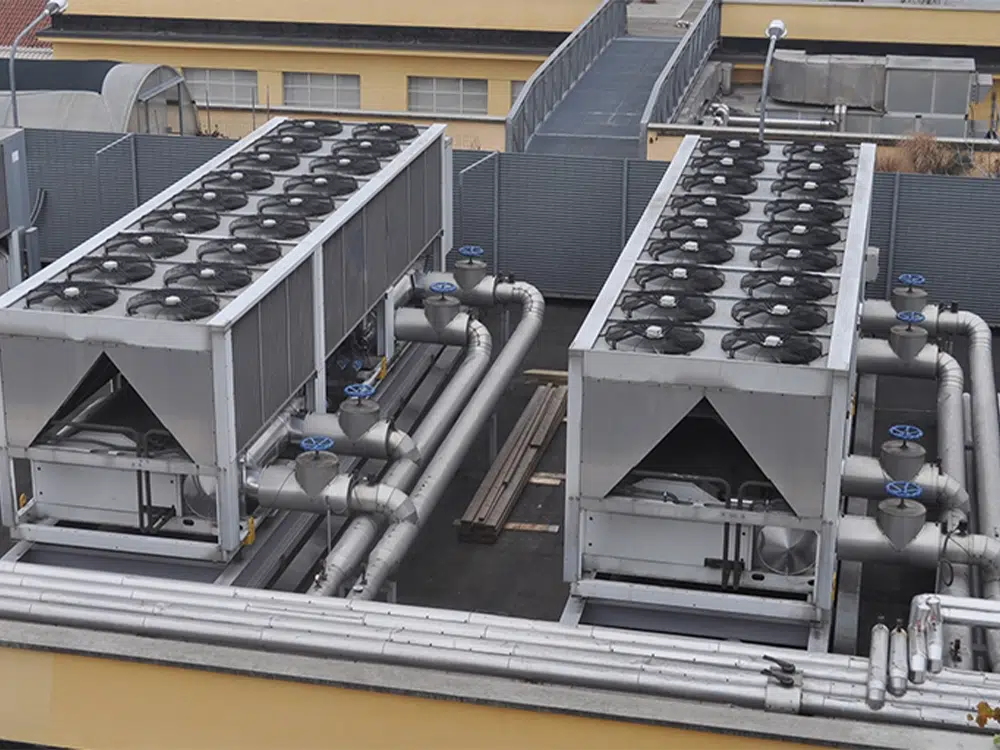

The products are widely used in petroleum, chemical industry, natural gas, metal smelting, electric power, printing and dyeing, mining, iron and steel, textile, food and beverage, environmental protection, pharmaceuticals, papermaking, high-rise building water supply and drainage engineering municipal engineering and other fields.

Service Guarantee

According to the actual needs of customers to determine the type and specifications of the valve, but also in accordance with the customer's special requirements of the design of customized, and provide customers with the process of valve design, manufacturing valves to meet customer requirements. And we can train relevant technicians for customers to master certain technical knowledge and valve maintenance skills. Provide new, special, difficult project construction technology consulting or develop appropriate construction program.

Industry Applications

News

Get in touch with us

If there are any questions you can leave us a message online, we will reply to you as soon as possible, if you want to know more detailed information welcome to contact us directly through the following mailbox.

We'll deliver:

- 30-minute quick response, reply within 24 hours after leaving a message

- Customized solutions for customer needs

- Keep track of the production process and minimize the production cycle time.

- Guide customers to install and debug, quick response after sale

E-mail inquiries: [email protected]