G641J pneumatic rubber lined diaphragm valve opening and closing is realized by the up and down movement of the valve stem driven by the pneumatic actuator. When the valve stem is in the upper position, the spherical diaphragm upward bending valve to form a conduction state. When the valve stem from up to down movement drives the valve spool to make the diaphragm bending, forced the diaphragm close to the valve seat area or, closed to the pipeline fluid path. Used to control corrosive or general corrosive media, the valve body cavity surface unlined or covered with a variety of optional rubber, suitable for different operating temperatures and fluid pipeline.

Working Principle

The valve closes when pressurized and opens when depressurized. Opening and closing are achieved by the pneumatic actuator driving the valve stem's vertical movement. When the valve stem is in the upper position, the spherical diaphragm bends upward, forming a conductive state. When the valve stem moves downward, it drives the valve plug to bend the diaphragm, forcing it to tightly seal against the valve seat area, thereby closing the pipeline fluid passage.

Product Features

- The diaphragm is replaceable, resulting in low maintenance costs.

- There is no stuffing box, so there is no external leakage.

- The streamlined flow path minimizes pressure loss.

- The elastic seal's opening and closing mechanism ensures no internal leakage.

- The fluid passage is straight, resulting in lower fluid loss and reduced wear.

- The valve body and cover are separated by an intermediate diaphragm, ensuring that components above the diaphragm—such as the valve cover and stem—remain protected from media corrosion.

- The sealing element is a resilient rubber diaphragm. Therefore, it also provides excellent sealing performance and minimal closing force.

- The surface of the inner cavity of the visual rubber diaphragm valve is covered with a variety of rubbers available from the Office. Therefore, it is characterized by superior corrosion resistance.

Product Parameters

Product Model | G641J-16C |

Valve body material | Cast Steel |

lining material | NR Natural Rubber |

Nominal pressure | ≤1.6Mpa |

Applicable medium | Purified Water, Inorganic Salts, Diluted Inorganic Acids, etc. |

Applicable temperature | ≤80°C |

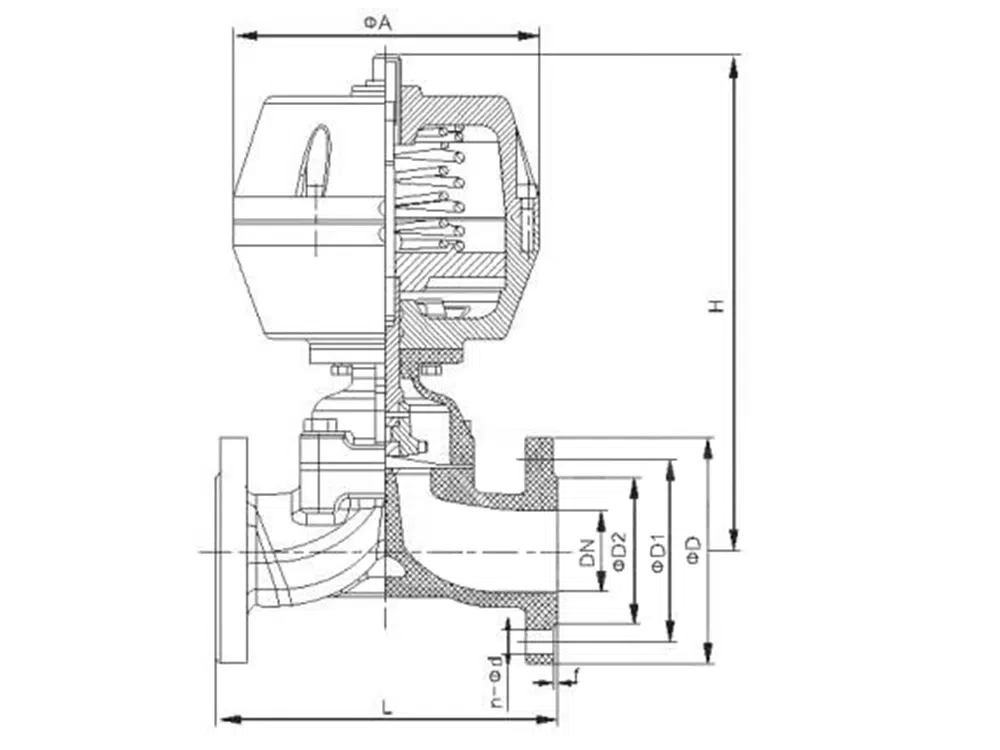

Product Size Reference

Nominal Diameter | L | D | D1 | D2 | n- φd | f | H | Gas source pressure (MPa) | Cylinder O.D. φA |

DN15 | 125 | 95 | 65 | 45 | 4-14 | 2 | 215 | 0.6 | 110 |

DN20 | 139 | 105 | 75 | 55 | 4-14 | 2 | 220 | 0.6 | 110 |

DN25 | 145 | 115 | 85 | 65 | 4-14 | 2 | 225 | 0.6 | 110 |

DN32 | 160 | 135 | 100 | 78 | 4-18 | 2 | 240 | 0.6 | 140 |

DN40 | 180 | 145 | 110 | 85 | 4-18 | 3 | 285 | 0.6 | 170 |

DN50 | 210 | 160 | 125 | 100 | 4-18 | 3 | 307 | 0.6 | 170 |

DN65 | 250 | 180 | 145 | 120 | 4-18 | 3 | 327 | 0.6 | 200 |

DN80 | 300 | 195 | 160 | 135 | 8-18 | 3 | 390 | 0.6 | 230 |

DN100 | 350 | 215 | 180 | 155 | 8-18 | 3 | 470 | 0.6 | 260 |

DN125 | 400 | 245 | 210 | 185 | 8-18 | 3 | 637 | 0.6 | 310 |