Hose valve is a kind of wear-resistant performance and corrosion resistance is very good valve, is the traditional ball valves, butterfly valves, diaphragm valves and other valves of good alternatives, the valve clear water test average life in 200,000 times. Applications for the mining industry: wet iron remover, ceramic filter, MGM tube membrane filter, Gore membrane filter, mine tailings slurry pipeline, mine mining unit slurry pipeline; construction machinery industry: mixing system of automatic weighing device, dosing system; metallurgical industry: steelmaking automatic slagging system; pharmaceutical industry: plastic bottles of I.V. fluid transport machine; sewage industry; sludge conveying Piping and other industries.

Product Features

- Pressure loss, clog-free, leak-free, impact-resistant.

- Particularly suitable for liquid-solid and gas-solid two-phase flows containing particles.

- The rubber hose sleeve features a fiber-reinforced structure, offering wear resistance and fatigue resistance.

Working Principle

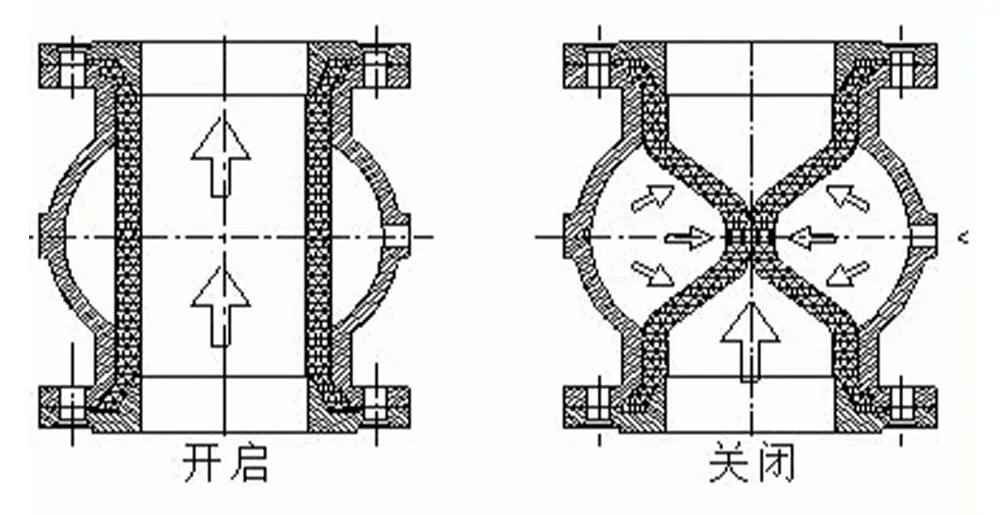

When no control medium is introduced, the cavity between the rubber sleeve and valve body communicates with the atmosphere, causing the sleeve to remain outwardly tensioned by fluid pressure. Due to the reinforcing fabric layers arranged at specific angles within the sleeve, axial and radial pressures balance each other, preventing changes in sleeve length or diameter under fluid pressure. Upon introducing control medium into the cavity between the sleeve and valve body, the sleeve deforms under medium pressure to achieve flow restriction.As shown below:

Product Parameters

Product Model | GJ841X-6L |

Valve body material | Aluminum |

Nominal pressure | ≤0.6Mpa |

food pole | Food-Grade Natural Rubber Tubing Sleeve |

Applicable medium | Compressed Air or Pressurized Water |

Tube sleeve material and temperature range | Natural Rubber: -5~80°C / EPDM Rubber: -5~120°C |

Pressure Range

Caliber (DN) | DN25–200 | DN250–300 |

work pressure | max4bar | max3bar |

Control Pressure | max6bar | max4.5bar |

Maximum differential pressure | 2bar | max1.5bar |

Product Size Reference

Nominal Diameter | L | H | D | K | N-L |

DN40 | 150 | 40 | 145 | 110 | 4-18 |

DN50 | 180 | 60 | 160 | 125 | 4-18 |

DN65 | 180 | 60 | 180 | 145 | 4-18 |

DN80 | 220 | 75 | 195 | 160 | 4-18 |

DN100 | 280 | 95 | 215 | 180 | 8-18 |

DN125 | 345 | 120 | 245 | 210 | 8-18 |

DN150 | 414 | 145 | 280 | 240 | 8-23 |

DN200 | 550 | 182 | 335 | 295 | 8-23 |

DN250 | 680 | 229 | 390 | 350 | 12-23 |

DN300 | 820 | 278 | 440 | 400 | 12-23 |